Space exploration is an important aspect of human evolution in the late 20th and in the 21st Centuries. Since the first Sputnik launch, there are now nearly 3,000 satellites orbiting Earth, each serving different purposes. One benefit of these for everyday life relates to communication, traffic, and navigation issues. The challenges that need to be overcome for space push technological limits, stimulating scientists and engineers to develop new products, which then become part of everyday life, such as freeze-dried foods, water purification systems, and scratch resistant lenses.

One of the next challenges is to build a Space Gateway to allow deep space missions, like the transit to Mars. This will require a huge joint effort by the international community to develop a series of technologies to allow humans to survive in hostile environments for long periods of time. Life support in space is, therefore, one of the main challenges at present.

Currently, a potential mission to Mars envisages supporting a crew of six astronauts, who will need to breathe, eat, and drink off-Earth for nearly two years. This will either require them to carry stock of huge quantities of oxygen, water, and food, or to use a circular recycling system to produce the oxygen, water, and food they will need during the course of the mission.

Several space agencies and research centers such as NASA, ESA and DLR are involved in investigating closed-loop recycling systems and related technologies. This has led to the production of:

- Demonstrators: such as the NASA Salad Machine and the THALES-Alenia Food Precursor Unit for bioregenerative Life support Systems in Space.

- Ground test facilities, like the EDEN-ISS in Antarctica, the MELiSSA Pilot Plant (MPP) in Barcelona, Spain, and the PACMAN Plant Cultivation Unit in Naples, Italy.

In the 1990s, the NASA Salad Machine represented a first step towards the development and testing of a demonstration unit that could produce food such as salad, while recycling a certain percentage of water, absorbing carbon dioxide, and producing oxygen by photosynthesis.

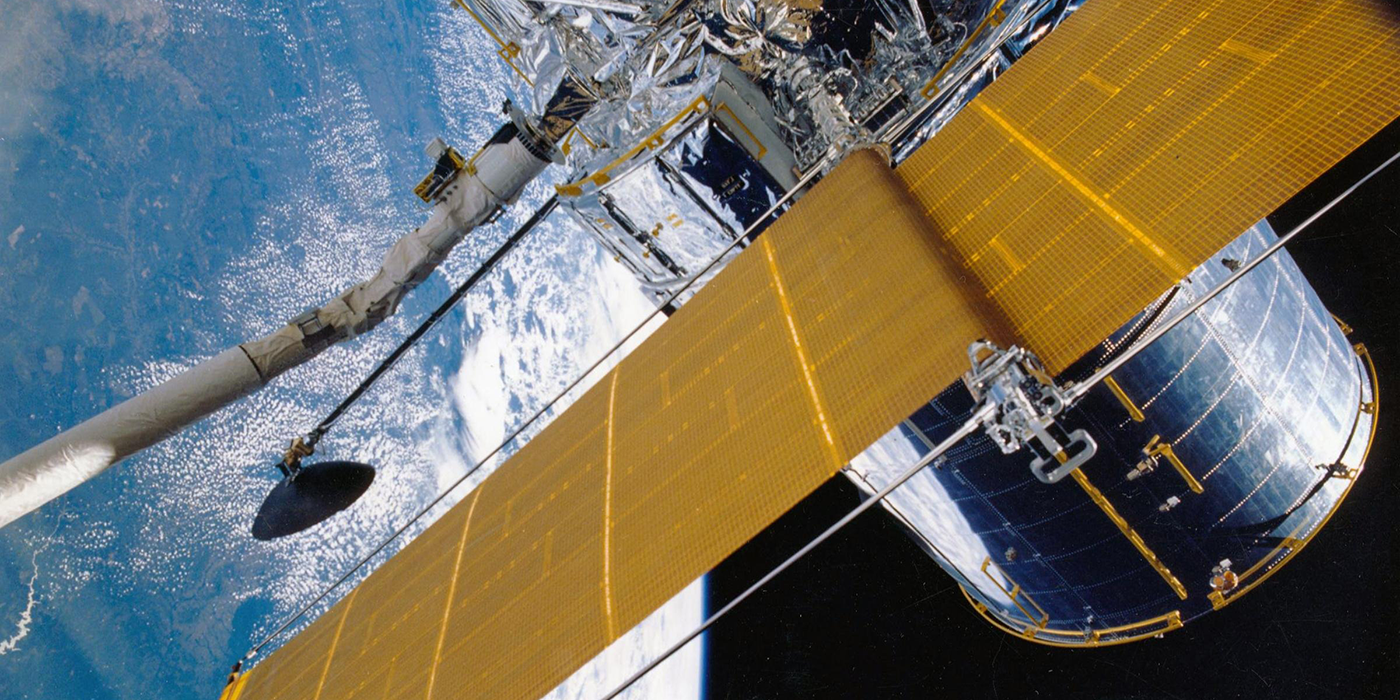

The EDEN-ISS project coordinated by the Deutsches Zentrum für Luft- und Raumfahrt – DLR (German Aerospace Center), where EnginSoft was responsible for the design of the air management process for the pilot test greenhouse in Antarctica (see Figs. 1 and 2), demonstrated that it was possible to produce different vegetables in a hostile environment.

Fig. 1: The Neumayer Station in Antarctica

Fig. 2: Computational fluid dynamics model for air management

Today, the most important activity in the Bioregenerative Life Support Systems (BLSS) is the Micro-Ecological Life Support System Alternative created by the European Space Agency (ESA) and known as the MELiSSA program. In the more than 25 years that the program has been running, it has developed a huge know-how from over 140 projects that have led to discoveries like Spirulina and successes like the MELiSSA Pilot Plant (MPP).

For the past 15 years, EnginSoft has been collaborating with ESA on the MELiSSA program, actively working on life support systems for space environments as a member of the MELiSSA Consortium, and has been directly involved in:

- The Advanced Life Support System Evaluator (ALISSE)

- Food Characterization Phase 1 for the heating, ventilation, and air conditioning at MPP

- The Scaling of Life Support Systems (SCALISS)

- The Greenhouse Module for Space systems (GMSS)

- Hydroponic Sub-System Engineering (-HYSSE)

- ENergy Resources Utilization Mapping (ENRUM)

- Air and Canopy Sub-compartment Analysis (ACSA)

- Atmospheric Sub-System Engineering (AtSSE)

- Operation and integration of the MELiSSA Pilot Plant (MPP) CCN5

- A PlAnt Characterization unit for a closed life support system – engineering, MANufacturing & testing (PACMAN)

- The Optimal System-in-system Control and ARchitecture (OSCAR).

The Arthrospira bacteria – better known as spirulina (see Fig. 3) – an edible protein-rich supplement that is highly resistant to radiation from outer space, has been a stable part of MELiSSA for many years thanks to its rapid growth and multiplication while converting carbon dioxide into oxygen. The following stage, however, is very ambitious.

Fig. 3: Arthrospira bacteria, better known as Spirulina

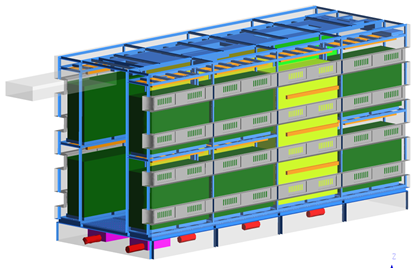

The MELiSSA Pilot Plant (MPP) – see Fig. 4, located at the Universidad Autonoma de Barcelona (UAB), has been used for integrating and testing the development and progress of all MELiSSA’s closed-loop technologies for more than ten years. It is the only laboratory in Europe set up to demonstrate a Closed-Loop Life Support System, a regenerative circular system that generates food, water, and oxygen from waste, carbon dioxide and minerals. This circular system has five compartments:

- Waste degradation

- Nitrification

- Air revitalization (photosynthesis with micro-algae)

- Food production (photosynthesis with higher plants)

- Mock crew (rat isolator).

EnginSoft has been particularly active in the food production compartment, contributing to the air management system, which enables the optimized evapotranspiration of plants during growth. Compartment 4 is also where the carbon dioxide is absorbed and regenerative oxygen is produced via photosynthesis since the plants’ evapotranspiration process produces water vapor that then condensates to produce recycled water.

Fig. 4: The MELiSSA Pilot Plant (MPP)

Finally, a state-of-the-art Plant Control Unit (PCU), shown in Fig. 5, was entirely developed by EnginSoft within the PACMAN project. This PCU is situated in Naples and consists of a growth chamber, specifically geared to growing plants and equipped with sophisticated sensors and environmental control systems. Its main objectives are to quantify the production of oxygen, the consumption of CO2, and the renewal of water, and to characterize the effects of different parameters such as temperature, light intensity, and nutritional composition on the behavior of the plants in order to enable the development of an artificial ecosystem.

In the course of this project, several engineering challenges were addressed focusing on the low leakage rate required for mass balance calculations. The required leakage rate (0.05% volume per hour) is very low compared to typical industry standards. Several techniques were implemented to achieve this.

Fig. 5: The PACMAN unit in operation

An advanced nutrient delivery system allows the composition and pH of the nutrient solution to be controlled by dosing the acid, base and eight stock solutions for a total of ten side tanks, each equipped with a peristaltic pump and scale for calculating the volume dosed (see Fig. 6).

Fig. 6: Lettuce growing test

This first experiment achieved two of the regeneration goals set by MELiSSA, namely producing oxygen and absorbing carbon dioxide, and recycling water. The oxygen is produced by a photosynthetic process and will allow future astronauts to have a spare supply of oxygen, thereby reducing the need to carry storage tanks for long-term space missions, whereas the water produced by the lettuce can be recycled and used as drinking water for the astronauts.

This major success also resulted in the latest , but no less important, project being developed by EnginSoft in this area, and in which it is now engaged - the Optimal System-in-system Control and ARchitecture (OSCAR) project.

Building on the expertise of the three partner entities (EnginSoft, Université Clermont Auvergne, and Sherpa Engineering) in modelling, simulation and control, the OSCAR study aims to map out the main paths towards bioprocess modelling and the predictive control of a complex life support system. It strives to combine emerging tools in synthetic biology, various classes and complexities of balanced models of microbial growth and bioconversion, process simulation and control, and finally, system-level evaluation, into a single coherent approach.

Drawing from and building upon the knowledge created in these numerous projects and its other areas of operation, EnginSoft will continue to contribute to the technologies necessary for the regenerative Life Support Systems needed to support the long-term manned space missions of the future!